- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Choose 4-Nitrobenzoic Acid

2025-08-27

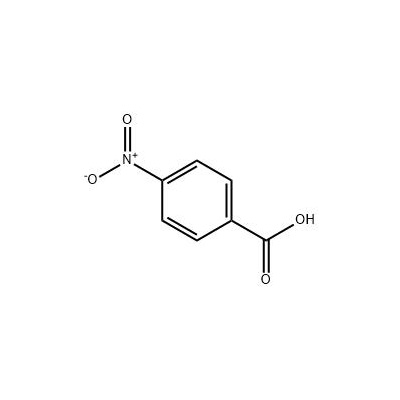

4-Nitrobenzoic Acid, a critical intermediate in pharmaceuticals, dyes, and specialty chemicals, plays a significant role in several high-value industrial sectors. With increasing demand for advanced intermediates and active pharmaceutical ingredients (APIs), understanding why 4-Nitrobenzoic Acid is so widely used has become essential for researchers, manufacturers, and distributors.

What Is 4-Nitrobenzoic Acid and Why It Matters

4-Nitrobenzoic Acid is an aromatic carboxylic acid derived from benzoic acid, with a nitro group positioned at the para location. This structural configuration imparts distinctive chemical and physical properties that make the compound invaluable for various industrial uses.

Key Chemical Properties

| Property | Specification |

|---|---|

| Chemical Formula | C₇H₅NO₄ |

| Molecular Weight | 167.12 g/mol |

| Appearance | Pale yellow crystalline powder |

| Purity | ≥ 99% (industrial/pharma grade) |

| Melting Point | 237 – 239 °C |

| Boiling Point | 360 °C |

| Density | 1.57 g/cm³ |

| Solubility | Slightly soluble in water, highly soluble in alcohols and ethers |

| Storage Conditions | Store in cool, dry, and ventilated areas, away from moisture and light |

4-Nitrobenzoic Acid’s stability and reactivity make it a versatile intermediate, especially in chemical synthesis. Its high melting point and controlled solubility allow manufacturers to leverage it in diverse formulations without compromising product stability.

Why Industries Prefer 4-Nitrobenzoic Acid

-

Purity-Driven Performance: High-purity grades support pharmaceutical and fine chemical synthesis.

-

Reliable Chemical Reactivity: The nitro group at the para position facilitates selective reactions.

-

Broad Industrial Demand: Essential across pharmaceuticals, dyes, pigments, and polymer production.

-

Stable Shelf Life: Properly stored material retains quality over extended durations.

The versatility of this compound means it underpins key advancements in manufacturing, making it indispensable in modern production ecosystems.

How 4-Nitrobenzoic Acid Is Used Across Industries

The applications of 4-Nitrobenzoic Acid span multiple industries due to its adaptable molecular structure and chemical behavior. Here are some of the primary sectors that rely on it:

Pharmaceutical Manufacturing

4-Nitrobenzoic Acid serves as a critical intermediate in synthesizing several active pharmaceutical ingredients (APIs). Its nitro-substituted aromatic ring is ideal for stepwise transformations, including reduction to amines or hydrolysis to other derivatives. Some applications include:

-

Production of antibiotics and anti-inflammatory drugs

-

Precursor for local anesthetics

-

Starting material in cardiovascular medicine synthesis

Because pharmaceutical regulations demand exceptionally high standards, 4-Nitrobenzoic Acid used in this sector is typically ≥ 99.5% pure and produced under GMP-compliant conditions.

Dye and Pigment Industry

This compound forms the backbone of many azo and anthraquinone dyes. Its nitro group readily participates in diazotization and coupling reactions, making it essential for:

-

High-performance textile dyes

-

Organic pigments for coatings

-

Specialty colorants for plastics and printing inks

Agrochemicals

In the agrochemical industry, 4-Nitrobenzoic Acid acts as an intermediate in the synthesis of pesticides, herbicides, and fungicides. Its molecular framework allows manufacturers to develop compounds with targeted biological activity while maintaining environmental stability.

Specialty Chemicals and Polymers

4-Nitrobenzoic Acid derivatives are also integrated into the production of advanced materials:

-

UV absorbers for polymers

-

Corrosion inhibitors

-

Electronic-grade materials for semiconductors

This wide applicability demonstrates its importance not just as a laboratory reagent but as a building block for innovations across industries.

4-Nitrobenzoic Acid FAQ

To help clarify common questions, here are two of the most frequently asked queries regarding 4-Nitrobenzoic Acid:

Q1: What are the critical factors to consider when choosing a supplier for 4-Nitrobenzoic Acid?

A:

When selecting a supplier, evaluate these factors:

-

Purity Consistency: Ensure product meets ≥ 99% purity standards for intended applications.

-

Regulatory Compliance: Check for ISO, GMP, and REACH certifications.

-

Batch Traceability: Every lot should include detailed Certificates of Analysis (CoA).

-

Packaging Integrity: Choose suppliers offering moisture-resistant, contamination-free packaging.

-

Global Shipping Expertise: Trusted suppliers provide temperature-controlled logistics for international deliveries.

Q2: How can you ensure safe handling during industrial-scale production?

A:

-

Engineering Controls: Install exhaust ventilation systems to minimize airborne exposure.

-

Personal Protection: Use chemical-resistant gloves, protective eyewear, and lab coats.

-

Automated Dosing Systems: Reduces direct human contact with raw material.

-

Spill Protocols: Have neutralizing agents and safety kits readily available.

-

Waste Disposal Compliance: Follow local and international hazardous waste regulations.

Implementing these measures safeguards workers, ensures product quality, and maintains compliance with environmental standards.

Why Partner with Run’an for High-Quality 4-Nitrobenzoic Acid

Choosing the right supplier is as important as selecting the right product. Run’an specializes in the production and distribution of high-purity 4-Nitrobenzoic Acid, meeting stringent international quality standards and providing flexible packaging solutions. With decades of experience, advanced facilities, and a strong commitment to safety, Run’an supports global customers across pharmaceuticals, dyes, agrochemicals, and specialty chemical sectors.

If you are seeking a reliable source for premium-grade 4-Nitrobenzoic Acid or need expert consultation for your industrial projects, contact us today to discuss your requirements and receive customized solutions.